Multi-Ripping Carbide Tip Saw Blades for Cutting Soft and Hard Wood

Basic Info

| Model NO. | 160mm |

| Certification | ISO9001:2008, CE |

| Tooth Form | Flat Tooth |

| Diameter | 230 |

| Function | Cutting |

| Shape | Hole Saw Blade |

| Coating | White Steel Saw Blade |

| Type | Carbide Saw Blade |

| Product Name | Circular Saw Blade |

| Key Selling Points | Sharp and Stable Quality |

| for Tree Species | Any Tree Species |

| for Machine | Multi Blade Saw Machine |

| Process Type | Laser Welded |

| Service | ODM OEM |

| Usage | Multi-Ripping Machine |

| Transport Package | One PCS in One Plastic Bag,One Bag in One White Bo |

| Trademark | Senji |

| Origin | Fujian, China |

| HS Code | 8202399000 |

| Production Capacity | 1000PCS/Month |

Product Description

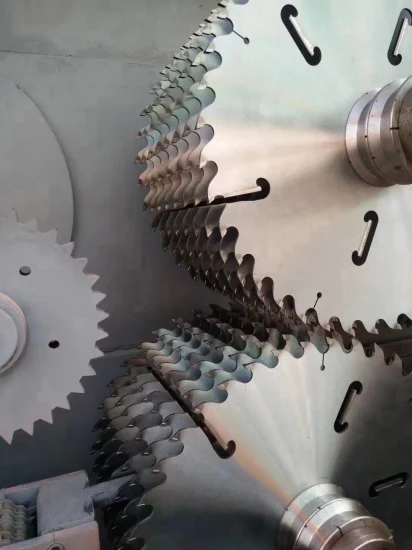

Alloy saw blade (Tungsten Carbide Tipped(TCT))75Cr1 steel body with good heat treatmentstable quality of each piece produced by advanced automatic machines Detailed Photos Automatic alloy welding sharp and durable

Suitable for various machines

Product Parameters

Saw balde Specifications

| Size | 230*2.2*1.7*40*30T+3 | |

| Machine | Popular for Multi Rip Saw | |

| Avantage | Long life, smooth cutting edge, low noise. | |

| application | Cut fresh wood into slices | |

| Logo | Can put customer's brand or our brand |

If the saw blade diameter is greater than 500mm, we will use a wooden box for packaging, and air cushion film inside and around the wooden box for shockproof.

Our AdvantagesOur company procucts have been export to europe,America,Southeast Asia ,Middle East and other regionsWe also can customize all kinds of cemented carbides products according to your drawing and samples.We will always provide you our best product and service.

Use and maintenance1. The alloy head of the tungsten carbide circular saw blade has a sharp and sensitive edge, so the alloy head must be carefully protected from damage during the movement, installation and removal of the saw blade.2. Before the saw blade is installed, the sundries on the main shaft and flange must be removed. The surface of the flange should be flat, clean and perpendicular to the shaft.3. Use the largest possible flange to make the operation of the saw blade more stable. The size of the flange should be consistent. The size of the flange is 1/3 of the diameter of the saw blade for better sawing effect.4. After the saw blade is installed smoothly, it should run idle for 30 seconds, and start cutting after confirming that everything is normal.5. When installing the saw blade, the flange nut must be moderately tight. If the saw blade is too loose, it will slip when rotating and cutting. If the saw blade is too tight, internal damage or deformation will affect the cutting effect.6. It is necessary to regularly remove the resin, debris and other sundries accumulated on the side of the saw teeth and saw board, because the accumulation of adhesives will increase the resistance and cause high energy consumption (in extreme cases, it will cause the motor of the machine to be burned) and Rough cutting quality. If the cutting edge is blunt at the same time, it may cause damage to the sawtooth.

FAQ1: Could I order one piece for sample to test the quality?Yes, We recommend to check the sample before order. Please inquiry us the Customer servicer, ,size,tree species, wood diameter, length, opening specificationsand etc.

2.What's the sample fee , could i get free sample?For some items with small size and ordinary color, free sample will be possible when the order is more than MOQ. For items with special color and size , we could charge for a little sample with freight in your side. But we promise to refund the sample price difference when certain quantity order is placed.3.How long will it take to ship?The delivery time is related to the order quantity and whether it is in stock. If the product is in stock, it can be dispatched as soon as possible; if it is not in stock, it will take about 15 working days to arrange the shipment.